We keep everything running

Pro-f makes your machine dance

- Improve functionality

- Make processes efficient

- Achieve higher productivity

You can count on us – our team of 18 experienced specialists in PLC and robot programming are united by a singular mission:

Pro-f Automatisierung offers you security when it comes to maximum functionality, efficiency and higher performance. We find the weak points in your system, proactively develop new solutions, and work meticulously until your machine is in tip-top shape.

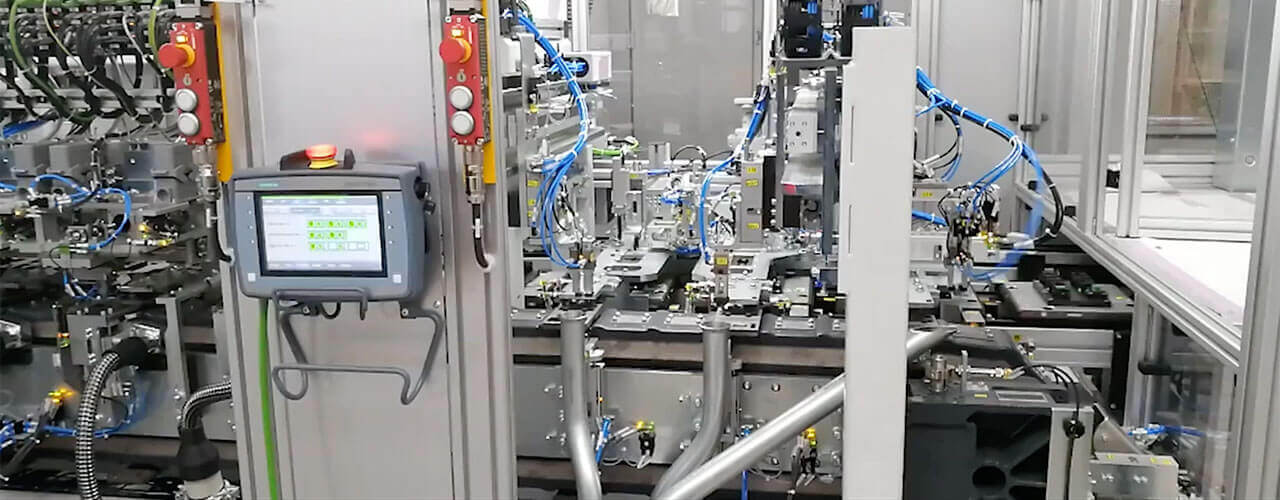

The programming of machinery controls is Pro-f Automatisierung’s core business for both small machines and comprehensive production lines.

Robot technology is a special field in which we program robots for a wide variety of applications – including Kuka, Abb, Stäubli and Fanuc.

We provide a clear and structured visualisation of information related to the production process, to ensure that systems run smoothly and intuitively.

As your contact partner at the control level, we guarantee extensive and secure data handling in the PLC and in combination with databases and control systems.

With a focus on energy efficiency, we show you the savings potential and actively help you to implement an energy management system that meets ISO 50001 standards.

Employee training is the key to being able to get the most value from the use of your systems. As experienced consultants, we provide an objective, unbiased outside view.

We put this and other questions to Pro-f owner and managing director Sven Finkemeyer, who is still actively involved in many projects along with his team of permanent programmers and automation experts.

In many cases, we’re called when either the machine is under construction, or an existing machine is being refitted and upgraded. Without the right controls, a plant is just a hunk of metal. We provide PLC and robot programming to ensure that the machine can run. Our focus during this is on efficiency and cycle time. We aren't satisfied until the entire system runs smoothly, which it should – or “dances” in sync, as it were, and thus fulfils its purpose.

Our mission also includes showing you untapped potential and calculating precisely how much additional performance a system could yield. For example, if it could have less downtime and a higher cycle time. Or how optimised energy management and improved visualisation of processes increase added value, as well as regular training for employees on the machinery. The factors are highly diverse and can only ensure smooth production with optimal interplay. This is why we take all of these aspects into consideration and consider ourselves a competence and solution provider in automation.

We are typically involved in collaboration with a production manager or main project leader in the field of control technology or machinery and plant maintenance. This could be a plant or operations manager or even a commercial manager, or in some cases, the company’s managing director. Our customers primarily include machine manufacturers and production companies in the German-speaking area and Europe, with over 150 employees. We are involved in various industries such as logistics and conveyor technology, the furniture industry, food, pharmaceuticals and chemistry, the packaging and automotive industry, and all other production companies that plan plant optimisation or renovations.

Along with planning and concept creation for new systems, we are currently very busy with machine renovations and plant optimisation. This also includes machine optimisation (cycle times and OEE – total system capacity), virtual commissioning (based on CAD data) as a cost-saving effect for customers, and the development of software standards and training concepts for employees and plant operators.

As a partner, we consider it important for smooth cooperation that the tasks arranged in the defined schedule be completed in accordance with the conditions agreed upon. Clear target agreements and transparency in the project through an open flow of information and corresponding documentation ensure clarity. We choose employees who are optimally suited for the task. The framework conditions are clarified, reviewed and communicated on an ongoing basis, for efficient operation.

Our customers get everything from one source, allowing them to focus on their core business. We are a reliable partner that listens with professional expertise and experience, and then passionately carries out the project on behalf of the customer. Our channels are extremely short and communication within the team is very fast. Our customers don’t need to wait long for a solution proposal. Another of our strengths is visiting a customer and proactively recognising potential of which the customer themselves had no idea. Then we provide just the right solution and relief at the same time.

Do you have more questions or want to learn more? Sven Finkemeyer will be happy to answer your questions in a short phone conversation and can give you a few examples of projects from long-term work in a wide variety of industries. Make an appointment for a personal consultation right now, by e-mail or by completing the contact form.

Does this sound familiar? The machines are stationary, nothing is running and no one knows what they’re supposed to be doing? The challenges our customers and partners face are many and varied:

The ideas, solutions and practical implementation of Pro-f provide relief and increase the productivity and added value of your machinery and plants. Some helpful examples?

As a provider of specialist skills for automation solutions in every industry, Pro-f shows you hidden potential and approaches to problem-solving, in addition to programming new machines, production lines and robots, as well as optimising existing production systems. All services offered are geared towards ensuring and improving the added value of production customers.

Pro-f sees itself as a family that is always there for each other. The employees are part of an active team culture and the company’s figures and development are open and transparent. Project teams are formed based on requirements, and personal further development is expressly encouraged.

Thanks to the open culture and many technical features that make fast exchanges possible, the group’s knowledge works well in daily work life. Flexible work schedules and mobile office solutions make the workplace family-friendly, and personal needs and employee circumstances are always taken into account to a great extent. If this sounds exciting to you, then apply for a job with us – unsolicited applications welcome!

Your contact partner

Claudia Siemoneit

We look forward to hearing from you!